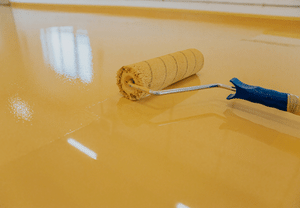

A great advantage of epoxy flooring is that it adheres to so many surfaces. This means that, if the floor or wall is already covered in tiles, it’s wholly appropriate to apply epoxy over the surface without removing them. This is a cost-effective way to completely transform a tiled floor or wall with an aesthetically pleasing, hard-wearing and contemporary surface.

Epoxy coating is one of the most versatile coverings on the market today. Its use certainly isn’t limited to only flooring – it’s perfectly suited to covering walls and ceilings as well. Contemporary, easy to install and hygienic, epoxy wall coatings integrate beautifully with both traditional and contemporary décor.

The flooring of a showroom must fulfil many roles. Not only does it need to be hard-wearing enough to withstand excessive footfall, be easy to clean, non-slip and conform to health and safety regulations, but it must also offer the perfect presentation of the goods on sale.

Flooring within a restaurant or café must meet rigorous industry standards. In addition, it also needs to be aesthetically pleasing – fitting with any colour scheme and décor – as well as being durable and easy to maintain.

When it comes to flooring, marine applications have very stringent requirements. Salt-water resistance is a given, as well as being able to withstand other harsh environmental elements.

Medical and healthcare settings require a flooring solution that’s easy to clean, resists microorganisms, is non-slip and can stand up to the rigours of heavy 24/7 use. Few industries are as dependent on long-lasting, sanitary flooring, where hygiene and cleanliness are of the utmost importance.

There are many reasons that epoxy is the ideal medium for office flooring. Such areas typically have heavy traffic, especially in regions where people tend to congregate – including breakout areas, coffee machines, kitchenettes, around the printer etc.

Selecting the right flooring option for exterior areas comes with many challenges. Epoxy offers one of the most modern, hard-wearing and economical options on the market today. Plus, they look amazing too!

Coving and coved skirting are well suited to a contemporary epoxy coating. In a variety of industries, including healthcare, food & beverage and pharmaceutical, it’s essential to carry out daily deep cleans.

Flooring in a commercial kitchen is up against daily wear and tear. Hot oil splatters, dropped utensils, liquid spills, abrasive or chemical cleaning products, high footfall, extremes of temperature… The list is endless.

The flooring choice for a garage and/or workshop has many demands. From heavy traffic through to constant spillages and – in the case of commercial facilities – complying with multiple regulations, there are many essential must-have features.

Interior spaces, be they domestic or commercial, are especially well-suited to epoxy flooring. Thanks to an almost infinite range of colours, multiple finishes and value for money, homeowners and businesses alike are turning to this modern flooring option.